How to Read Continuity on a Digital Multimeter

Often electronic devices have problems that you can't see with your eyes. Circuits can be damaged, shorted, or disconnected, and you would never know just by looking at the device, whether it's a fuse, wire, or circuit board. If you need to see whether a circuit is closed and working, use the continuity test function on a multimeter.

If you haven't heard of this before, it might seem a little complicated. Understanding a real-world scenario might help it become more clear. If your headphones stop working and the cable still looks good, you could use a continuity test to determine whether the cable is actually carrying the current or whether there is a break in the middle.

What is Continuity?

Electricity works across pathways that require connections to each part of the path to move the current from one place to another. If there's a disruption in that electricity and one of the sections isn't working, it's likely that your electronic device won't work either.

When you use a multimeter to test for continuity, you're checking to see whether the electrical pathway is open and the current is flowing between each point.

What Is the Continuity Test Looking for?

The essential explanation is that a continuity test looks for continuity of electrical flow. It ensures that electric current is moving through a device or wire.

The test checks whether each part of the path is connected on a closed-loop. If the switch is open between the two points being tested, then the loop is open, and there is no continuity.

Most multimeters will beep when a closed-loop and operational continuity are detected. Generally, if there is no beep, it's open and not continuous. However, models without a continuity test may be able to measure the resistance but won't give you a beep alert to inform you about continuity.

Continuity tests can help you diagnose invisible problems with all kinds of electronics.

For example, if you're using a continuity test on a motherboard, you might be checking to be sure you haven't blown part of the board that you can't see. Many people use it to test the different leads that go into the ATX power connector.

How Does the Continuity Test Work?

When you touch two contact points with the probes, the multimeter sends a small current into the contacts. It measures the resistance in the circuit with this current and reports back to you whether the circuit is working.

Some multimeters have different settings for when it beeps or displays a number. It's essential to read the guide that came with the meter to understand what you're hearing and seeing on the readout.

What Safety Measures Are Required for a Continuity Test?

You should always remove anything you're testing from any source of power. If you're testing something in your home connected to your fuses, turn off the primary power source for the house. It can be hazardous to do this kind of testing on a device getting power from another source.

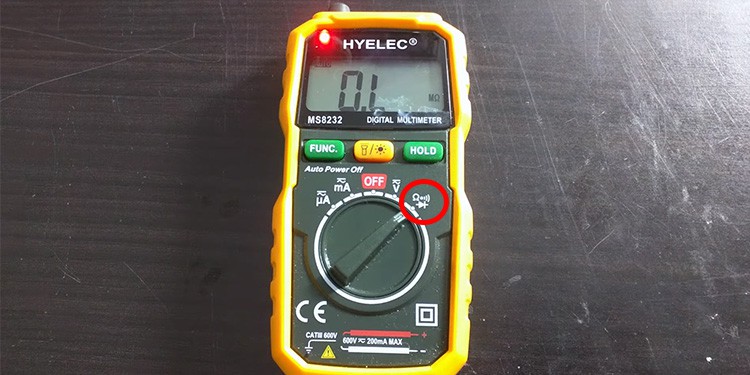

What Symbol on the Meter Means Continuity Test?

This will vary depending on which multimeter you're using. Look for a diode, which is like an arrow on a line pointing to a wall. It might also be a wave symbol. Check your manual to be sure.

How to Test Continuity With a Multimeter

Using a multimeter to test continuity should be pretty straightforward, and the process might vary a bit depending on the model. However, if you check your manual, you should find differences before starting and know where your steps diverge.

- Remove the device you're testing from any type of power. You do not want to leave it plugged in when using the multimeter.

- Insert the end of the left probe into the appropriate port on the multimeter.

- Insert the end of the right probe into the appropriate port on the multimeter.

- Turn on the multimeter. You want to turn the dial to the Ohms or Continuity Test setting.

- Set the range on the multimeter to the resistance you're testing for on the range setting. You want to use the lowest possible resistance if you're testing switch contacts or other things with a low-resistance value.

- Adjust the dial to the type of test you want to run. In this case, you're looking for a continuity test. If you aren't familiar with the icons on the dial, refer to your manual.

- Touch the two probes together and listen for the beep that shows you they're working. Some models may not make a sound, and you'll have to refer to the screen to see whether it's working. Expect to see zero or low value reading on the screen. If you see a 1, it means that your probes are broken.

- Put one probe on a contact point and the other probe on another contact point.

- Listen for the signal or watch the screen to see whether there is a working circuit between them. After you get the reader, remove the probes from the device.

This should let you know whether the circuit is functioning and whether there is continuity between the two places you touched. However, you can also use a continuity test with a multimeter to find which wire in a cable is matched to a wire on the other end of the cable.

Cables are often made from twisted bundles of wires, and you can't always tell which on the left end goes with which on the right end. If you need to know, test in the following manner.

- Turn on the multimeter. The individual wires on either side of the cable must be exposed for this process to work. The cable should not be plugged into any devices.

- Touch the left probe to a wire on the left side of the cable.

- Touch the right probe to a wire on the right side of the cable. If it detects continuity, you should hear a sound or see it on the screen. If it doesn't, continue.

- Move the right probe to another wire on the right side of the cable. Wait for a beep or indication on the screen that there is or is no continuity.

- Continue testing wires on the right side until you find the one that registers continuity. Ensure the left side probe is always in contact with the left wire you're testing as you move the right probe from one wire to the next.

This can help you know exactly which wire is connected even when you can't follow the path visually.

What Do the Continuity Test Results Mean?

If the thing you're testing is broken or not working, you'll see a test reading of OL, which means open loop. You also might see an unexpectedly low or high resistance. In that case, you might need to get a new part if you can't repair that component.

There are two kinds of test devices to consider: load and non-load components.

- Non-load components are like fuses or switches. They don't restrict the power that flows through them. Expect to see low resistance ratings, for example, 0.1 ohms.

- Load components consume power and operate at a specific resistance, which varies depending on the device. One example of a load component is a motor. You'll have to check what resistance is required and see what the multimeter is measuring.

As long as a non-load component shows some resistance, it should function fine. However, a load component with resistance that registers but is too low for the device won't work correctly. If the resistance is outside the workable range, you may need to repair or replace it.

Sometimes, finding a connection with no continuity means having a shorted wire. It could also signal that it's loose, and properly attaching it might fix the problem.

As always, read your manual to understand the output that you see after performing the test.

Remember, even wires and electronics that are gently and properly used will degrade. Everything has a lifespan. So even if you don't see any problems when you look at a device, there could be an invisible problem.

Knowing the basics of how to test continuity with a multimeter can help you troubleshoot all kinds of problems, whether you're reusing old computer parts or trying to figure out why an appliance isn't working.

Multimeters - Resistance and Continuity - Electronics Basics 14

Source: https://www.technewstoday.com/how-to-test-continuity-with-a-multimeter/